ENGINEERED & LAMINATED LOG SYSTEMS

The Warmth of Authentic Wood. The Precision of Modern Engineering.

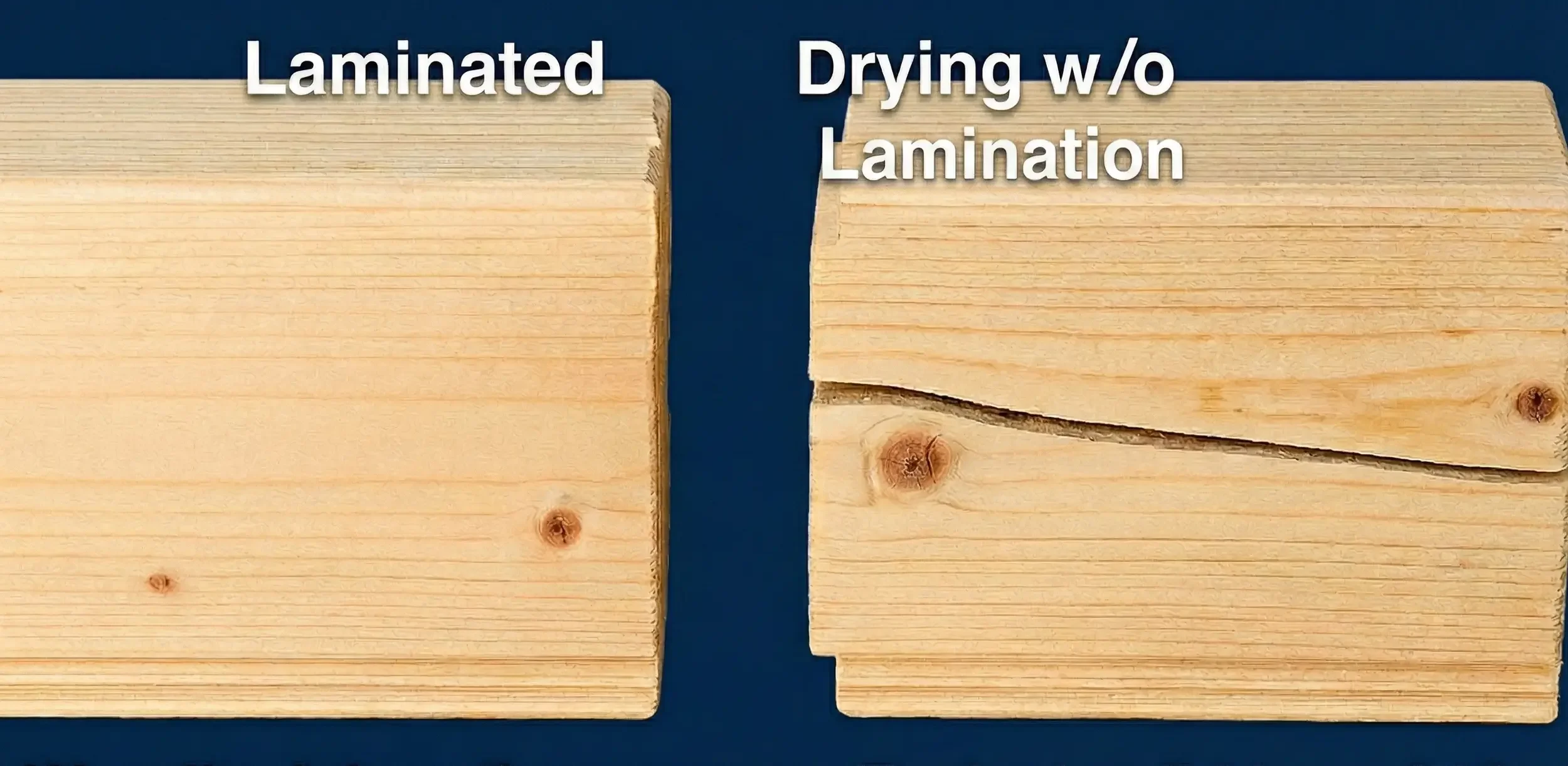

For over 40 years, U.S. Log & Timber’s founders have been an industry authority in laminated log manufacturing and construction. With 7 filed patents - we take building with engineered timber seriously. US Log and Timber combines the traditional aesthetics of solid wood homes with the dimensional stability, strength, and predictability of modern mass-timber engineering. Unlike traditional solid log walls that shrink, settle, and crack, our engineered laminated wall systems are manufactured from kiln-dried lumber layers bonded under high pressure.

The primary advantage of our system is stability. Traditional solid logs—even when kiln-dried—contain internal stresses that cause them to twist, warp, and check (crack) as they acclimate to your climate.

The result is a structural wall system that delivers superior stability, improved thermal performance, and long-term durability without the settling, cracking, or ongoing maintenance historically associated with solid log construction.

WHAT ARE ENGINEERED LAMINATED LOGS?

Engineered laminated logs are manufactured from two to six layers of kiln-dried lumber bonded together under high pressure using exterior-rated structural adhesives. Each lamination is dried to a controlled moisture content before assembly, then cured using radio-frequency pressing to form a single structural timber.

This engineered process produces a wall system that behaves predictably under load, resists shrinkage, and maintains tight tolerances over time.

Our system is not just a "log cabin"; it is a high-performance building envelope designed to meet rigorous modern codes.

ENGINEERING AND STRUCTURAL PERFORMANCE

Engineered laminated log walls are designed in accordance with recognized building standards, including the International Building Code (IBC) and applicable ASCE 7 structural load criteria. Published span tables, section properties, and allowable stresses are used to establish design parameters, with project-specific engineering calculations available where required.

By redistributing natural wood characteristics across multiple laminations, engineered timbers achieve higher strength-to-weight ratios than solid sawn logs of comparable size. This allows for longer spans, larger openings, and reduced reliance on interior load-bearing walls.

DIMENSIONAL STABILITY AND ZERO-SETTLE DESIGN

US L&T Display Wall

One of the biggest financial and maintenance benefits of our system is the elimination of wall settlement. Unlike traditional log homes, engineered laminated wall systems do not require settling allowances, adjustment jacks, or oversized framing cavities above doors and windows. Windows, doors, interior finishes, and mechanical systems can be installed immediately after structural assembly without adjustment periods or long-term maintenance related to wall movement.

No Screw Jacks Required: Because our timbers are kiln-dried and laminated, they do not shrink in height. You never need to install or adjust screw jacks.

No Settling Allowances: We do not need to leave large gaps (settling spaces) above your windows and doors.

Because laminated logs are manufactured from kiln-dried lumber with uniform moisture content, post-installation shrinkage is minimal. Every lamination is dried to a controlled moisture content of 8–12% before assembly. This ensures the logs do not shrink or move after installation.

US L&T 8-Lam Timber

Airtight Seal: Our precision-milled tongue-and-groove profiles create a continuous air seal. Because the wall doesn't settle, these seals remain intact permanently without the need for chinking or re-sealing.

Code Authority: All components are designed in accordance with the International Building Code (IBC) and applicable ASCE 7 load criteria.

Certification: Our manufacturing complies with ANSI/AITC A190.1, with quality verified by independent inspection agencies.

US L&T Insul-Lam™

Strength: Engineered timbers achieve higher strength-to-weight ratios than solid sawn logs, allowing for longer spans and larger window openings. A laminated cedar timber is approximately 70% stronger than a solid log of equal size.

Thermal Performance & Energy Efficiency

Our laminated walls offer superior energy efficiency, often outperforming conventional framing in real-world scenarios due to "Thermal Mass." The solid mass of the timber dampens indoor temperature swings, offering effective performance up to 30% higher than static R-values suggest.

We also offer a rigid, insulation core laminated timber that meets an R-37 for our Alaska and northern customers, meeting strict energy codes in cold climates.

Fire Safety & Performance: A common misconception is that log homes are a fire risk. In reality, heavy timber construction performs exceptionally well in fire events due to "charring".

Predictable Safety: In a fire, mass timber chars at a slow, predictable rate of approximately 0.6 mm per minute.

Structural Integrity: This char layer insulates the inner core of the wood, allowing the wall to maintain its load-bearing strength long after standard framing would have failed.

Ratings: Our standard laminated walls meet or exceed 1-hour and 2-hour fire-resistance ratings.

Hurricane Ready: Our systems are capable of meeting high wind load requirements, including exceeding Dade County (Miami) 180 MPH wind load standards. We are able to build on high coastal pilings because of our low weight and strength affordably.

Last, but not least, because we ship to both coasts - including South Florida, the Caribbean and the Hawaiian Islands strength in high winds is vital. Hurricanes, strong ocean storms, tidal surges must be structurally mitigated. It is very expensive to do so with frame construction.

AIR, WATER, AND VAPOR MANAGEMENT

Precision-milled tongue-and-groove profiles create continuous compression-fit joints that support airtight construction. Because laminated log walls do not settle, air seals remain intact over time without reliance on ongoing adjustments or re-chinking.

Engineered laminated log walls are compatible with modern flashing details, drained rainscreen assemblies, and window integration systems. As a vapor-open material, solid wood assemblies allow controlled drying, reducing the risk of trapped moisture common in cavity-based wall systems.

Kiln-dried lumber has some industry standards that allow 15-19% moisture content. Our laminated wall material is kiln-dried to 8-12% moisture content.

Laminating allows the use of second-growth cedar, thereby sparing old-growth cedar trees.

FIRE PERFORMANCE AND Wildland-Urban Interface CODE STRATEGY

Heavy timber construction resists fire through predictable surface charring rather than rapid combustion. As the outer layer chars, it insulates the structural core and helps maintain load-bearing capacity during fire exposure.

Where required by code or Wildland-Urban Interface regulations, laminated log wall systems can be paired with ignition-resistant or non-combustible exterior cladding assemblies to achieve extended fire-resistance ratings.

WOOD SPECIES, GRADES, AND FINISH OPTIONS

USLT engineered laminated logs are available in multiple wood species, including Western Red Cedar, Douglas Fir and Larch, Ponderosa Pine, and Alder, with additional species available by request.

Premium Materials & Aesthetics: While many competitors use "Service Grade" lumber for their laminations, U.S. Log & Timber refuses to compromise on beauty.

Decorative Grade: We use an architectural, decorative grade lumber for our exterior faces. This means tight, small knots and a furniture-quality, smooth finish rather than a rough, industrial look.

Multiple surface textures and aesthetic grades allow the system to support architectural styles ranging from contemporary mass-timber design to traditional timber aesthetics, without compromising structural performance.

Customization: We can laminate different species for the interior and exterior. For example, you can have a Cedar exterior for weather resistance and a Ponderosa Pine interior for a brighter interior look.

DURABILITY AND MAINTENANCE

With standard exterior protection and routine maintenance appropriate to species and exposure, engineered laminated log wall systems are designed for long-term service life without the recurring maintenance demands of traditional log homes.

APPLICATIONS: Engineered laminated log systems are suitable for exterior and interior walls, roofs and ceilings, balconies and mezzanines, floor and roof decking, and a wide range of residential, commercial, and institutional structures.

SUMMARY: Engineered laminated log wall systems deliver the natural beauty of real wood construction with the performance, predictability, and durability of modern mass-timber engineering, eliminating the structural and maintenance limitations historically associated with solid log homes.

The Smart Choice for Log Homes: U.S. Log & Timber has removed the liabilities of traditional log home construction—the rotting, the shrinking, the air leaks, and the maintenance—while keeping the soul and beauty of the wood.

Our laminate log/timbers are an affordable luxury, natural and healthy home solution for the planet earth. Contact us today to discuss your project specifications and engineering requirements. We welcome your interest.